5 Reasons Your Industrial AC Bill High

(And How to Calculate Real Costs)

Stop wasting profits on inefficient cooling. Expert analysis for factories and plants in Gujarat.

The Hidden Cost of Cooling

Summer in Gujarat brings soaring temperatures, and for factory owners, it brings the dreaded spike in operating expenses. Industrial AC bills high costs are not just a seasonal annoyance; they are a direct hit to your manufacturing margins. Whether you are running a pharmaceutical unit in GIDC or a chemical plant in Dahej, the story is the same: production costs rise, and profits shrink, all because your cooling systems are demanding more power than they should.

Why is this happening? Often, the culprit isn’t the electricity rate itself, but the hidden inefficiencies within your system. Old industrial chiller efficiency drops significantly over time. Wrong tonnage calculations lead to systems that work too hard (undersized) or cycle too frequently (oversized). Furthermore, a simple lack of professional service leads to dirty AC coils electricity cost spikes that could easily be avoided.

Stop Guessing Your Expenses

Most factory owners don’t even know how much their AC actually costs per hour. We built a free tool to tell you exactly how much you are spending.

👉 Click Here to Calculate Your AC Power CostInstant result. No signup required.

5 Reasons Your Industrial AC Bill High

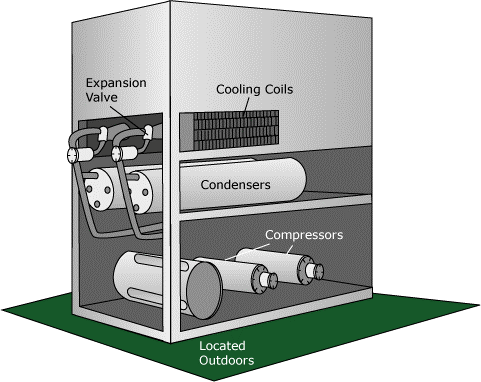

1. Dirty Condenser Coils & Poor Maintenance

When was the last time your industrial HVAC power consumption was audited? Dust and grime act as an insulator on your condenser coils. This forces the compressor to work harder and run longer to achieve the same cooling effect. A dirty coil can increase energy consumption by up to 30%. Regular preventative HVAC maintenance is the cheapest way to lower your bill immediately.

2. Aging Equipment & Low SEER Ratings

If your chillers or package units are over 10 years old, their EER vs SEER industrial ratings are likely obsolete. Modern inverter technology and variable frequency drives (VFD) can adjust motor speed to match the cooling load, whereas old units run at 100% capacity regardless of demand. Retrofit old HVAC systems or plan for a replacement to see ROI within 24 months.

3. Improper Insulation and Leaks

Poor warehouse insulation costs you money every second. Whether it’s unsealed ducts, open loading dock doors, or lack of thermal insulation in the roof, you are essentially trying to cool the outdoors. Detect HVAC air leaks and seal them to ensure the cold air stays where it belongs—inside your facility.

4. Incorrect Tonnage Sizing

An oversized industrial AC unit will short-cycle (turn on and off rapidly), leading to massive power spikes and equipment wear. An undersized HVAC system will run continuously without ever reaching the set point. Both scenarios lead to high commercial electricity bill causes that are avoidable with proper load calculation.

5. Power Factor & Peak Demand Penalties

Many industries in GIDC face HVAC peak demand charges and factory power factor penalties. If your motors are inductive loads without capacitor banks, your kVA demand rises, increasing your bill even if your kWh usage remains stable. Industrial AC power factor correction is a critical technical fix.

BONUS TOOL: Industrial AC Tonnage Calculator

Estimate your required cooling capacity instantly.

Pros & Cons of Regular AC Maintenance

PROS (Benefits)

- ✓ Lower electricity bills immediately.

- ✓ Extended lifespan of screw chiller and compressors.

- ✓ Better air quality for factory workers.

- ✓ Reduced risk of sudden breakdown during summer.

- ✓ Maintains manufacturer warranty validity.

- ✓ Higher ROI on HVAC calculation.

- ✓ Detects minor gas leaks before they become major.

CONS (Of Neglect)

- ✗ High industrial AC bill every month.

- ✗ Frequent compressor failures.

- ✗ Poor cooling impacting production quality.

- ✗ Noise pollution from strained motors.

- ✗ Expensive emergency industrial AC repair costs.

- ✗ Safety hazards from water leaks or electrical shorts.

- ✗ Complete system replacement needed sooner.

Comprehensive Industrial Cooling & Lab Services

We don’t just fix ACs. We provide end-to-end solutions for all your thermal management needs in Vadodara and Gujarat.

Industrial & Commercial AC

Complete solutions for factories, offices, and plants.

- AC Service Vadodara

- Central AC Repair

- Chiller Repair Services

- Roof Top Units (RTU)

- VRF/VRV Systems

Cold Storage & Refrigeration

Preserving your products at the perfect temperature.

- Cold Room Repair

- Deep Freezer Repair

- Walk-in Freezers

- Water Cooler Repair

- Industrial Dehumidifiers

Laboratory Incubator & Equipment

Precision repair for sensitive lab environments.

Brands We Service

We provide expert service for all major brands (Note: We are an independent multi-brand service provider).

Estimated Service Price List (Vadodara)

| Service Type | Description | Starting Price (INR) |

|---|---|---|

| Split/Window AC Service | Jet pump cleaning, filter cleaning, gas check | ₹499 – ₹799 |

| Industrial Chiller Checkup | Diagnosis, pressure check, amp check | ₹1500 – ₹3500 |

| Gas Charging (R32/R410/R22) | Full gas top-up with leak testing | ₹2200 – ₹4500 |

| Incubator/Lab Equipment Repair | Sensor calibration, heating element fix | On Inspection |

| Installation/Uninstallation | Standard fitting with copper pipe (extra if needed) | ₹1200 – ₹2500 |

*Prices vary based on capacity, location (GIDC vs City), and spare parts required.

GIDC & Industrial Areas Served

- ✓ Makarpura GIDC

- ✓ Savli GIDC

- ✓ Por GIDC

- ✓ Waghodia GIDC

- ✓ Halol GIDC

- ✓ Karjan GIDC

- ✓ Nandesari GIDC

- ✓ Ankleshwar GIDC

- ✓ Dahej SEZ

- ✓ Bharuch Industrial Area

Local Vadodara Areas

- ✓ Alkapuri

- ✓ Manjalpur

- ✓ Karelibaug

- ✓ Gotri

- ✓ Vasna Road

- ✓ Fatehgunj

- ✓ Subhanpura

- ✓ Akota

- ✓ Gorwa

- ✓ Sama

We Buy & Sell Used Industrial ACs

Looking to upgrade? We purchase second-hand chillers, scrap ACs, and old HVAC plants at the best market rates in Gujarat.

Get a Quote for Your Old ACFrequently Asked Questions

How often should I service my industrial AC?

For factories running 24/7, we recommend quarterly service (preventative maintenance) to keep electricity bills low.

Can dirty coils really double my bill?

Yes. Dirty coils reduce heat transfer, causing the compressor to run constantly and draw higher amps, leading to massive bills.

Do you repair lab incubators and shakers?

Yes, we offer incubator repair service near me in Vadodara for pharmaceutical and research labs, including CO2 and BOD incubators.

What areas do you cover in Vadodara?

We cover all of Vadodara city, including Alkapuri, Manjalpur, and all major GIDC areas like Makarpura, Savli, and Halol.

Do you provide AMC services?

Yes, we offer Annual Maintenance Contracts (AMC) for industrial and commercial HVAC systems.

What is the service charge for a visit?

Visiting charges depend on location and equipment type. Please call us at +91 97272 57141 for a quote.

Do you buy old scrap ACs?

Yes, we buy and sell used/second-hand and scrap ACs, chillers, and industrial plants.